Automatic CBD oil filling machine 10ml 30ml e-liquid perfume round bottle filling machinery

Product Description

Products Description

Performance, features, configuration descriptionPurpose and introduction:

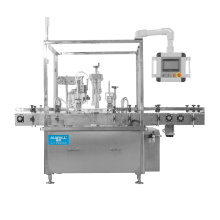

This machine is developed by our company on the basis of absorbing advanced foreign technology, and is a special equipment for spray filling. Suitable for filling and capping of round and shaped bottles of various materials and nozzles of variousspecifications. Adopt disc positioning type filling, disc positioning type upper sprinkler, screw cap, high degree of automation, solve the inconvenience of manual sprinkler, this machine uses peristaltic pump filling, pneumatic capping, lifting cap,man-machine interface Control has the advantages of accurate filling measurement, stable capping, simple operation and so on. In a leading position in the country. Widely used in medicine, daily chemical and other industries. Fully comply with GMP requirements!

Features:

1. Automatic nozzle management and automatic upper nozzle, replacing manual, high efficiency.

2. PLC control, peristaltic pump filling, high filling accuracy.

3. Imported cam splitter provides precise equal division of work stations.

4. Reasonable design, stable operation and easy maintenance.

5. It is made of SUS304 and 316L stainless steel, which fully complies with the new GMP requirements.

Technical parameter:

Applicable specifications 5-200ml (different bottle specifications need to replace the mold)

Production capacity 60-80 bottles / min

Filling accuracy ≤ ± 1%

Power 220V / 50Hz

Cover rate ≥98%

Air consumption 0.8-2m³ / h 0.3-0.8Mpa

Power 2 kw

Machine net weight 650 kg

Dimensions 2000 * 1200 * 1600mm

This machine is developed by our company on the basis of absorbing advanced foreign technology, and is a special equipment for spray filling. Suitable for filling and capping of round and shaped bottles of various materials and nozzles of variousspecifications. Adopt disc positioning type filling, disc positioning type upper sprinkler, screw cap, high degree of automation, solve the inconvenience of manual sprinkler, this machine uses peristaltic pump filling, pneumatic capping, lifting cap,man-machine interface Control has the advantages of accurate filling measurement, stable capping, simple operation and so on. In a leading position in the country. Widely used in medicine, daily chemical and other industries. Fully comply with GMP requirements!

Features:

1. Automatic nozzle management and automatic upper nozzle, replacing manual, high efficiency.

2. PLC control, peristaltic pump filling, high filling accuracy.

3. Imported cam splitter provides precise equal division of work stations.

4. Reasonable design, stable operation and easy maintenance.

5. It is made of SUS304 and 316L stainless steel, which fully complies with the new GMP requirements.

Technical parameter:

Applicable specifications 5-200ml (different bottle specifications need to replace the mold)

Production capacity 60-80 bottles / min

Filling accuracy ≤ ± 1%

Power 220V / 50Hz

Cover rate ≥98%

Air consumption 0.8-2m³ / h 0.3-0.8Mpa

Power 2 kw

Machine net weight 650 kg

Dimensions 2000 * 1200 * 1600mm

1.Adopt human-computer interface,PLC controller,easy to operate 2.Use frequency converting control,easy to adjust the filling speed,automatic count 3.Automatic stop,no bottle no filling. 4.Round turn table for positioning filling,stable and reliable . 5.High precision CAM indexing gage control.

Filling heads(Photoelectric detection, no bottle no filling)

Capping head(Adjustable tightness of capping)

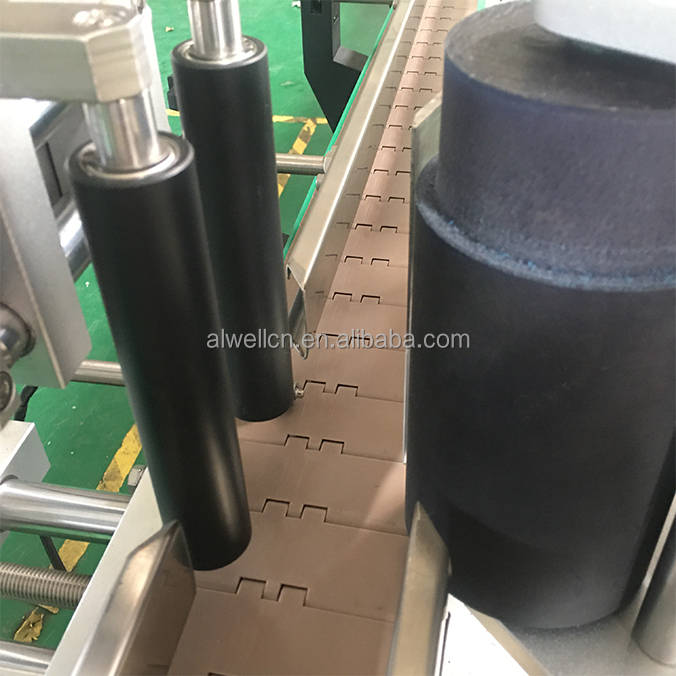

Advantages 1.Adopt standard PLC, touch screen, stepper motor, photo sensor electric control system. High safety coefficient and labeling precision. 2.Complete English writing human-machine interface; Has advanced fault remind function and operation teaching function; convenient to use and easy to maintain. 3.No step speed regulation on labeling speed, transportation speed and bottle division speed, easy for worker to adjust according to reality. 4.Completely achieve round product labeling automatically and quickly, It has multi-function, which can be used either for one kind of label or for many kind of labels. 5.The clever design which allow user to mechanically adjust some structure combination and label winding, makes it easy to adjust the labeling position freely (it can be fixed easily after adjustment). 6.Adopt vertical labeling method, can be work alone or join in the production line Option:

1. hot printer/ code machine

2.automatic feeding function

3. Add Labeling Machine head

4. Wrap around labeling function

5. Other function (as customer’s requirement).

Application

Wide range of applications

Now our products are widely used in food,medicine,manufacture,printing,logistics and other industries, They are used inproduction's quality inspection, classification, as well as in the product packaging weigher test.They had helped customers togreatly reduce the labor costs, to improve the production efficiency, and greatly to improve the percent of pass, help customers

to improve the industry competitiveness.

to improve the industry competitiveness.

Company Introduction

Shanghai ALWELL have more than 2000 Square meters factory.

We have 10 years experience in the industry. Factory direct sale,we can prove very competitive price and durable quality guarantee Our main products are check weigher, Metal detector, weight sorting machine, Liquid Filling Machine, Powder filling machine,Syringe Filling Machine,Capping Machine,Labeling machine, and supporting production lines.

We have 10 years experience in the industry. Factory direct sale,we can prove very competitive price and durable quality guarantee Our main products are check weigher, Metal detector, weight sorting machine, Liquid Filling Machine, Powder filling machine,Syringe Filling Machine,Capping Machine,Labeling machine, and supporting production lines.

Our Services & Strength

We have a large stock.

We can fast delivery within 5 days at the earliest. We support OEM.

We can fast delivery within 5 days at the earliest. We support OEM.

After-sales service

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.. We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

3..We provide one year warranty

4.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

5 .12 Months guarantee and life-long technical support.

6.Your business relationship with us will be confidential to any third party.

7. Good after-sale service offered, please get back to us if you got any questions.

2.. We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

3..We provide one year warranty

4.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

5 .12 Months guarantee and life-long technical support.

6.Your business relationship with us will be confidential to any third party.

7. Good after-sale service offered, please get back to us if you got any questions.

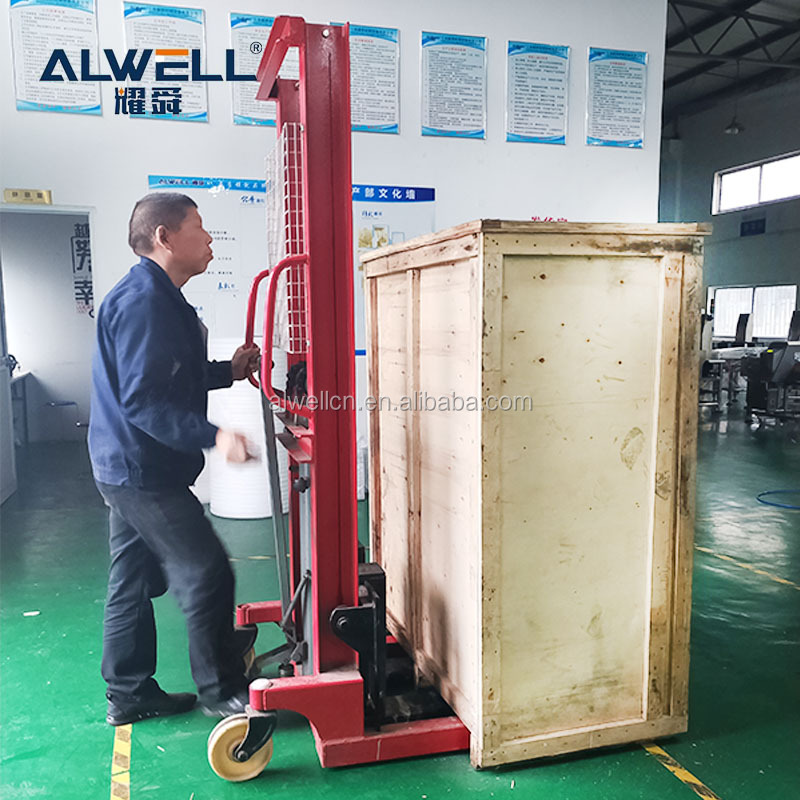

Packing&Shipping

The machine will be fixed and then packed in wooden cases.Fast Delivery!

The earliest delivery is 5 days after payment.

Related Products

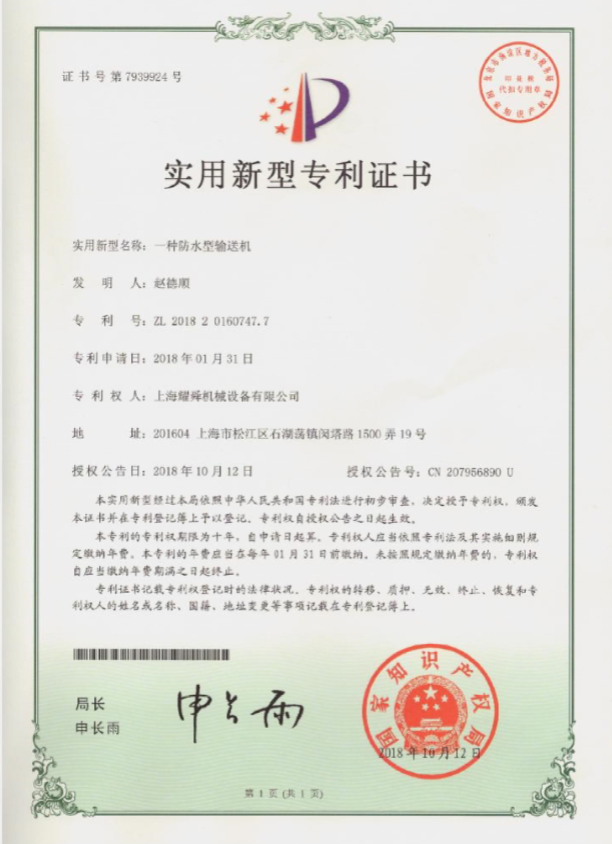

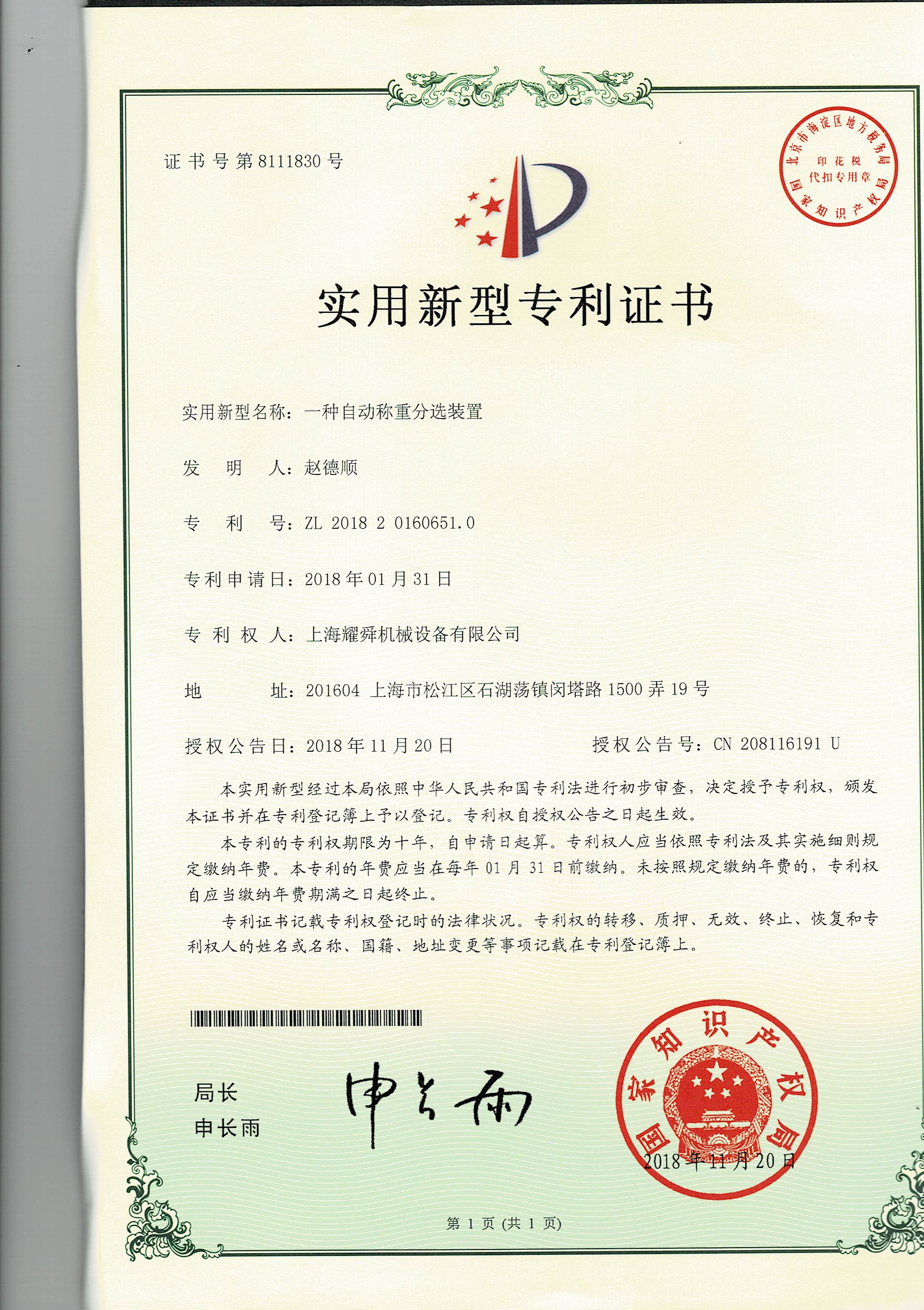

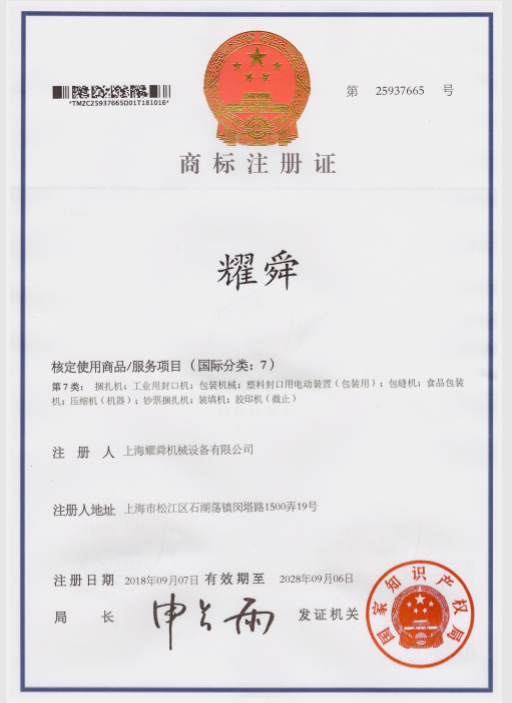

Certifications

Customer Show

FAQ

1.Are you manufacturer or trader? Where are your factory located?

We are manufacturer and we are located in Shanghai,China.

2.What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

Sea shipping, air Shipping, and international express. And after confirming your order ,we would keep you updated of production details of emails and photos.

3.How long is your warranty?

12 months free warranty, life-long maintenance.

4.Are you provide product metal parts and provide us technical guidance?

Wearing parts,for example, motor belt,Disassembly tool(free) are what we could provide.And we can give you technical guidance.

5.What are your company requests of payment terms?

TT,L/C,International Credit Card.

6. What is the validity time of the quotation?

15 days since quotation date

7. What is the delivery time?

Within 15 days after receipt of your deposit.

8. Are you a manufacturer?

Yes, we are a manufacturer, and we can provide the competitive price and good quality.

We are manufacturer and we are located in Shanghai,China.

2.What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

Sea shipping, air Shipping, and international express. And after confirming your order ,we would keep you updated of production details of emails and photos.

3.How long is your warranty?

12 months free warranty, life-long maintenance.

4.Are you provide product metal parts and provide us technical guidance?

Wearing parts,for example, motor belt,Disassembly tool(free) are what we could provide.And we can give you technical guidance.

5.What are your company requests of payment terms?

TT,L/C,International Credit Card.

6. What is the validity time of the quotation?

15 days since quotation date

7. What is the delivery time?

Within 15 days after receipt of your deposit.

8. Are you a manufacturer?

Yes, we are a manufacturer, and we can provide the competitive price and good quality.

Any questions or needs contact us (products . trade problem,how place order,shipping fee checking and so on)

Contact us:

Mark

Remark: In view of our products model different ,widely used in many industries ,in order to improve communication efficiency . so pls indicate the filling materials and canning capacity before sending the inquiry. so we can choose the suitable one for you,send detail and quotation to your email .thank you for your understanding .

Product Categories : Filling Machine > Spray bottle filling machine

Premium Related Products

Other Products

Hot Products

PFS-F350 pedal sealer with codeBF-900LW film sealing machine for spartsSolid-Ink Coding Continuous Band Sealer panit body 68Solid ink film sealer DBF-1000PCBS-1100 film sealing machine for bagPFS750A film heat plastic bag sealing machine with 750mmDBF-900L automatic film sealing machine food traysPFS-F350 Sealing Machine pedal Impulse sealing machine in wenzhouDBF-900L automatic film sealing machine food trays 8Heat-shrink packing machineBS400 4 6vacuum sealing machine for pouch DZ1000SS304 vacuum sealing machine for big pouch DZ-500HP1000L-I From WENZHOU Hot sale juice filling machineBS400L Heat Shrinking Packing Machinery wrapping machine600HI Factory price manual plastic bag sealing machine900HI seam sealing machine,plastic sealing machine